TRUSTED BY

On-Demand Manufacturing Automation Solutions We Provide

Inventory Management Solution

Build robust inventory management solutions to monitor inventory levels in real time, automate reorder processes, and reduce carrying costs. Enhance stock accuracy ensuring your manufacturing operations are always at their peak.

Supply Chain Management Systems

Build software that automates your supply chain processes with our expert developers. The supply chain management software aids production planning, procurement, shipping, demand and supply forecasting, and quality control.

Database Management System

We design and develop manufacturing factory automation solutions streamlining data integration, transfer, and security. Clients can utilize database management systems to enhance decision-making, boost productivity, and increase profit margins.

CRM Software

Elevate your customer relationships with CRM software exclusively designed for manufacturing. Streamline communication, manage leads, and boost sales with user-friendly CRM software that perfectly aligns with your business objectives.

Production Monitoring and Management Solutions

Take control of your production processes with our production monitoring and management solutions. Monitor real-time data, optimize workflows, and ensure timely deliveries, all from a centralized dashboard.

ERP Software

Build a custom ERP software that integrates all facets of your manufacturing business. Manage finances, supply chain, human resources, and more from a single platform, improving decision-making and operational efficiency.

Ready to Automate Your Manufacturing Process?

Connect with our experts to build custom manufacturing automation solutions that boost efficiency and productivity.

Build Custom Manufacturing Automation Systems

Tired of inefficient, repetitive tasks and bottlenecks in your manufacturing process? We can help you transform your workflow with custom manufacturing factory automation solutions with tailored features aligning with your needs. Our engineers will work closely with you to understand your specific challenges. From repetitive tasks like material handling and assembly to complex quality control measures, our engineers will craft an innovative system that seamlessly integrates with your existing infrastructure.

We leverage the latest technology to design and implement solutions that streamline your production processes, enhance efficiency, and reduce operational costs. With our customized approach, you can achieve higher productivity, improved quality control, and greater flexibility to adapt to changing market demands. Let's discuss how custom automation can unlock the full potential of your manufacturing operation.

Build Custom Manufacturing Automation Systems

Key Features of Manufacturing Automation Solutions

With manufacturing automation solutions, businesses can improve efficiency and precision in production. These systems, including robots, programmable machines, and AI, boost productivity, reduce errors, and free up human workers for more complex tasks.

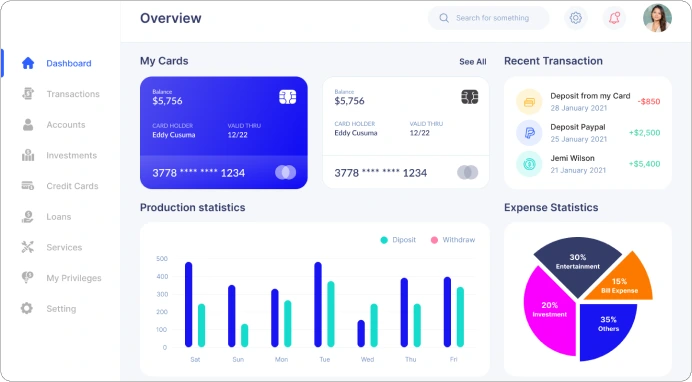

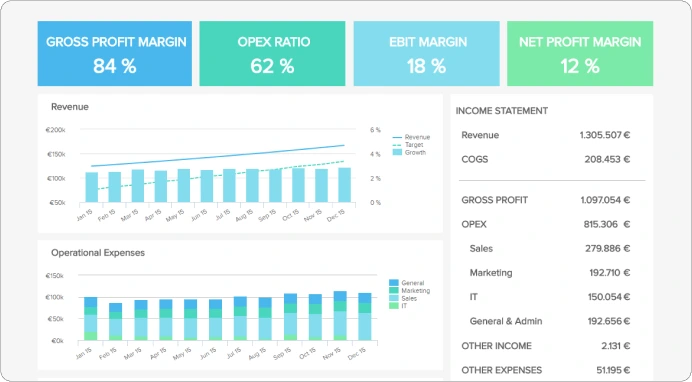

Data Analysis & Reporting

Data Analysis & Reporting

Collect and analyze data from various sensors and machines with advanced tools to identify trends, bottlenecks, and areas for improvement. Generate detailed reports on performance metrics, production statistics, and compliance.

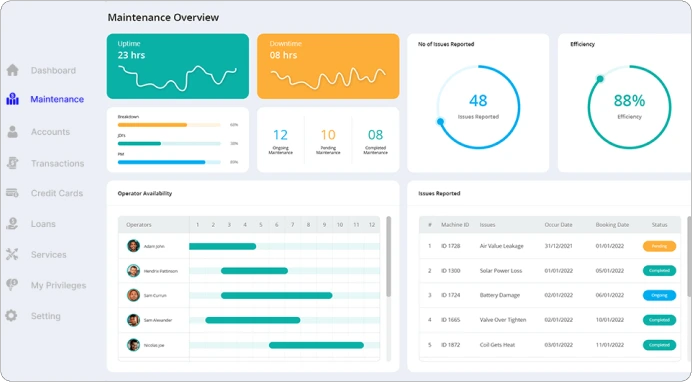

Predictive Maintenance

Avoid unplanned equipment downtime with predictive maintenance using machine learning algorithms. Track the health of machinery and equipment to predict failures before they occur. Schedule maintenance activities automatically based on machine condition and usage data.

Predictive Maintenance

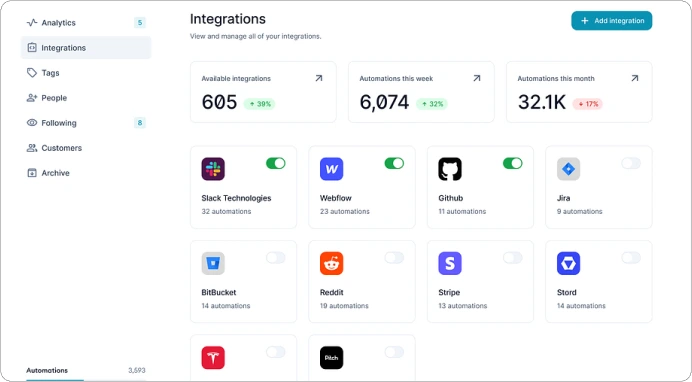

Seamless Integration

Seamless Integration

Manufacturing factory automation systems must seamlessly integrate with IoT sensors, devices, and other systems. This integration enables real-time monitoring and control of equipment to detect issues and synchronize production data.

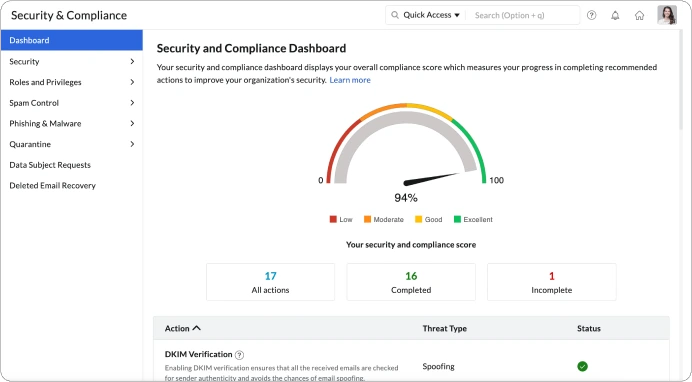

Security & Compliance

Prioritize security for sensitive data, intellectual property, and user information through encryption and secure communication protocols. Define user roles and permissions to ensure data security and operational integrity.

Security & Compliance

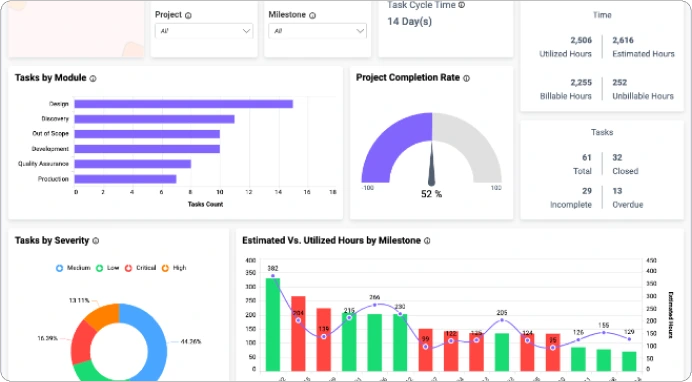

Real-time Monitoring and Control

Real-time Monitoring and Control

The admin dashboard provides a comprehensive view and control of the manufacturing process with real-time data. Get instant alerts for equipment malfunctions, production delays, or deviations from the set parameters.

Location Tracking

Admins can use geographic information systems (GIS) to locate and monitor workers' whereabouts and track their movements precisely. The system can automatically trigger safety protocols if workers enter restricted or hazardous areas, ensuring safety and compliance.

Location Tracking

Benefits of Automated Manufacturing Solutions

Automation does require an initial investment in setting up the systems and processes. However, it's an investment for the future that will streamline your work and make it more efficient. Automated solutions take over repetitive tasks, freeing you for more creative or strategic work.

Increased Efficiency

Automation tools perform tasks faster and without fatigue, or errors. These tools can operate around the clock to maximize production capacity and efficiency. With automation, manufacturers can avoid costly downtime, directly translating to higher output volumes.

Quality and Consistency

Automation technology minimizes defects and produces consistent, high-quality goods according to programmed specifications. Automated processes uniformly perform repetitive, tedious tasks each time and offer comprehensive coverage surpassing human capabilities.

Flexibility and Scalability

Programmable automation allows manufacturers to quickly scale output up or down and introduce new products to align with demand shifts. This agility enables faster responses to evolving customer demands and market conditions.

Reduced Labor Costs

Automating manual tasks reduces labor requirements and associated wage expenses. However, automation also creates new jobs to supervise automated processes, allowing remaining workers to focus on tasks that require human judgment, creativity, and problem-solving abilities.

Safer Work Environment

Automating hazardous tasks mitigates health and safety risks to human employees. They no longer need to interact directly with dangerous equipment or materials, improving working conditions and protecting employees from harm.

Greater Sustainability

Manufacturing process automation enhances energy efficiency and material savings compared to manual production by optimizing resource consumption and minimizing waste. It benefits both the environment and the manufacturer through tangible cost reductions.

Ready To Automate Your Production?

Streamline your operations, boost efficiency, and cut costs with custom manufacturing automation solutions.

Our Success Stories

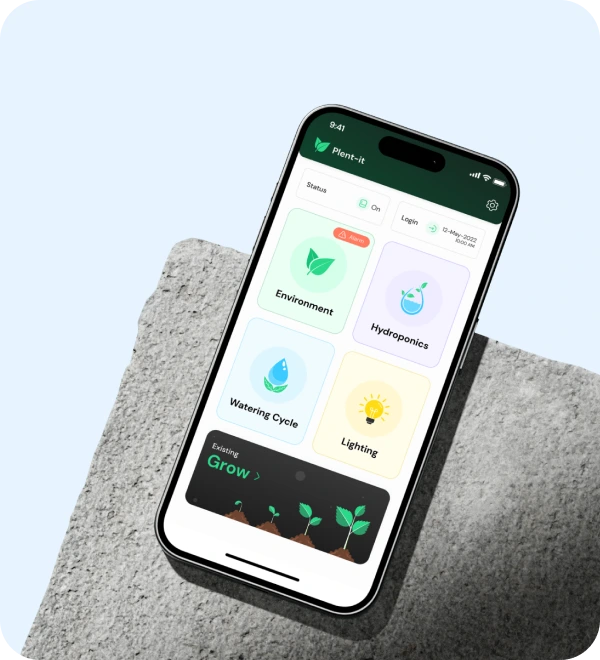

- Plent.it App

- QAView

- ActiView

Plent.it App

Plent.it was developed for agricultural businesses of all sizes. This comprehensive app simplifies farm management, connects you with vital resources, and streamlines operations for better yields and profits. It’s a sustainable way to grow new plants and keep track of them. Plus, businesses get environment updates as well.

Category

- IoT

Tech Stack

- Web

- iOS

- Android

QAView

QAView is an AI-powered logistics solution that tracks, counts, and validates packages in real time during the loading process. It detects damages, seal issues, and missing labels, offering live insights via camera feeds and dashboards. Easily integrates with existing systems for smarter, faster, and error-free inventory management.

Category

- Manufacturing

Tech Stack

- Next.js

- NestJS

- PostgreSQL

ActiView

ActiView is an AI-powered productivity and security monitoring platform that converts everyday video into actionable insights. It tracks employee behavior, detects inactivity, flags security breaches, and generates real-time productivity reports. With industry-specific adaptability, smart analytics, and live camera...

Category

- General & Manufacture

Tech Stack

- Swift

- Kotlin

- PayPal

- AWS

Hire Skilled Manufacturing Automation Developers

Hiring skilled manufacturing automation engineers is crucial for leveraging automation's full potential in your production processes. Our experts have the technical knowledge and experience to design and implement automation systems that enhance efficiency, productivity, and quality. With a team of seasoned automation developers, we enable businesses to choose the ideal resources for their project requirements. As your reliable manufacturing automation development company, we help businesses quickly cover resource gaps.

Hire Skilled Manufacturing Automation Developers

Technology Stack For Manufacturing Automation Software

Count on our technical expertise to build robust manufacturing automation solutions. Our experienced developers stay ahead of the latest technological trends, delivering solutions that are efficient, scalable, and perfectly aligned with your business objectives.

Programming Languages & Framework

Database

Data Processing (Real-time)

Cloud Services

Machine Learning and Analytics

Monitoring and Logging

Containerization and Orchestration

Automation Protocols

Manufacturing Automation Software Process

We follow a rigorous development process, prioritizing clear communication and collecting feedback. The agile approach allows multiple iterations, ensuring maximum client satisfaction.

Planning & Research

- Understand manufacturing industry

- Analyze competitors

- Validate automation app idea

- Planning timeline and resources

Wireframing And UI/UX Design

- Design Automation app wireframes

- Define features & layout

- Developing Windows app structure

- Take feedback

Development

- Write & implement code

- Front & back-end development

- Add automation software features

- Organize different panels

Quality Assurance

- Functional Testing

- Assess Code & responsiveness

- Bug & security fixing

- Test usability and compatibility

Launch & Maintenance

- Plan the launch

- Deploy manufacturing app

- Implement marketing strategies

- App maintenance and support

Ready to Future-Proof Your Factory?

Increase output, improve quality, and gain a competitive edge with top-notch manufacturing automation software.

Why Choose Moon Technolabs?

Why Choose Moon Technolabs?

Moon Technolabs is the choice for a highly skilled and experienced team that offers top-notch software solutions. Our customer-focused approach and knowledge of modern technologies such as AI, IoT, and blockchain ensure innovative and efficient solutions. We offer complete services, emphasizing quality assurance, adaptability, and open communication.

Why Clients Trust Us?

FAQs

01

How much does manufacturing automation software cost?

The cost of manufacturing automation software can vary widely based on the system's complexity, the specific features required, and the scale of deployment. For a detailed estimate tailored to your needs, please get in touch with us for a consultation.

02

Do you provide post-launch maintenance?

We provide comprehensive post-launch maintenance services to ensure your software remains up-to-date and operates smoothly. Our maintenance packages include regular updates, bug fixes, performance optimization, and technical support.

03

Do you provide the source code?

Yes, we provide the source code upon project completion. We aim to ensure you have full control and ownership of your software, allowing for future modifications and enhancements as needed.

04

How can manufacturers ensure the security of sensitive data within their mobile apps?

Manufacturers can enhance security by implementing robust encryption to protect data during transmission and storage, enforcing strict user authentication protocols to control access, and complying with industry regulations such as GDPR or CCPA. Regular security audits and updates are essential to safeguard against evolving threats and vulnerabilities.

05

Will you help integrate the manufacturing automation app with other systems?

Yes. Our expert manufacturing app engineers will seamlessly integrate the software with other systems.